The Contractor’s Guide to Hiring a Qualified Concrete Cutting Partner

Concrete cutting is one of the most critical and underestimated components of a construction project. A single mistake in this phase can cause costly delays, structural damage, or safety violations. Yet many contractors still select cutting partners based on price alone, rather than capability, experience, and professionalism.

If your project involves concrete cutting, coring, or selective demolition, hiring the right partner will directly impact your timeline, safety record, and overall quality. This guide breaks down what to look for in a qualified concrete cutting contractor and how to make an informed decision that protects your reputation and your budget.

1. Start with Experience, Not Equipment

Modern cutting equipment is powerful and precise, but tools alone do not guarantee results. Experience is what determines whether those tools are used safely and effectively.

Look for a company with proven experience across multiple environments — commercial, industrial, and municipal. The ability to work in complex conditions such as hospitals, data centers, or active roadways speaks volumes about a contractor’s professionalism.

At Kansas City Coring & Cutting, for example, our crews are trained to handle everything from tight indoor coring to bridge deck removals. That range of experience means we understand how to adapt techniques and mitigate risk in any environment.

Actionable Tip:

Ask for examples of past projects that resemble your scope. Request references from clients who can speak to performance under similar conditions.

2. Verify Safety Record and Compliance

Concrete cutting carries inherent risk. A qualified partner should not only have the proper safety programs in place but also prove they follow them daily.

Request to see the contractor’s Experience Modification Rate (EMR) and safety certifications. A strong EMR — like our .78 rating — reflects a consistent record of safe, incident-free operations. It also signals that the contractor invests in training and equipment maintenance, not just production speed.

Ask whether the company uses wet cutting methods to control silica dust and comply with OSHA 1926.1153 standards. A partner that prioritizes health and safety protects your team as much as their own.

Actionable Tip:

Never assume safety compliance. Require documentation. A professional cutting contractor will provide it without hesitation.

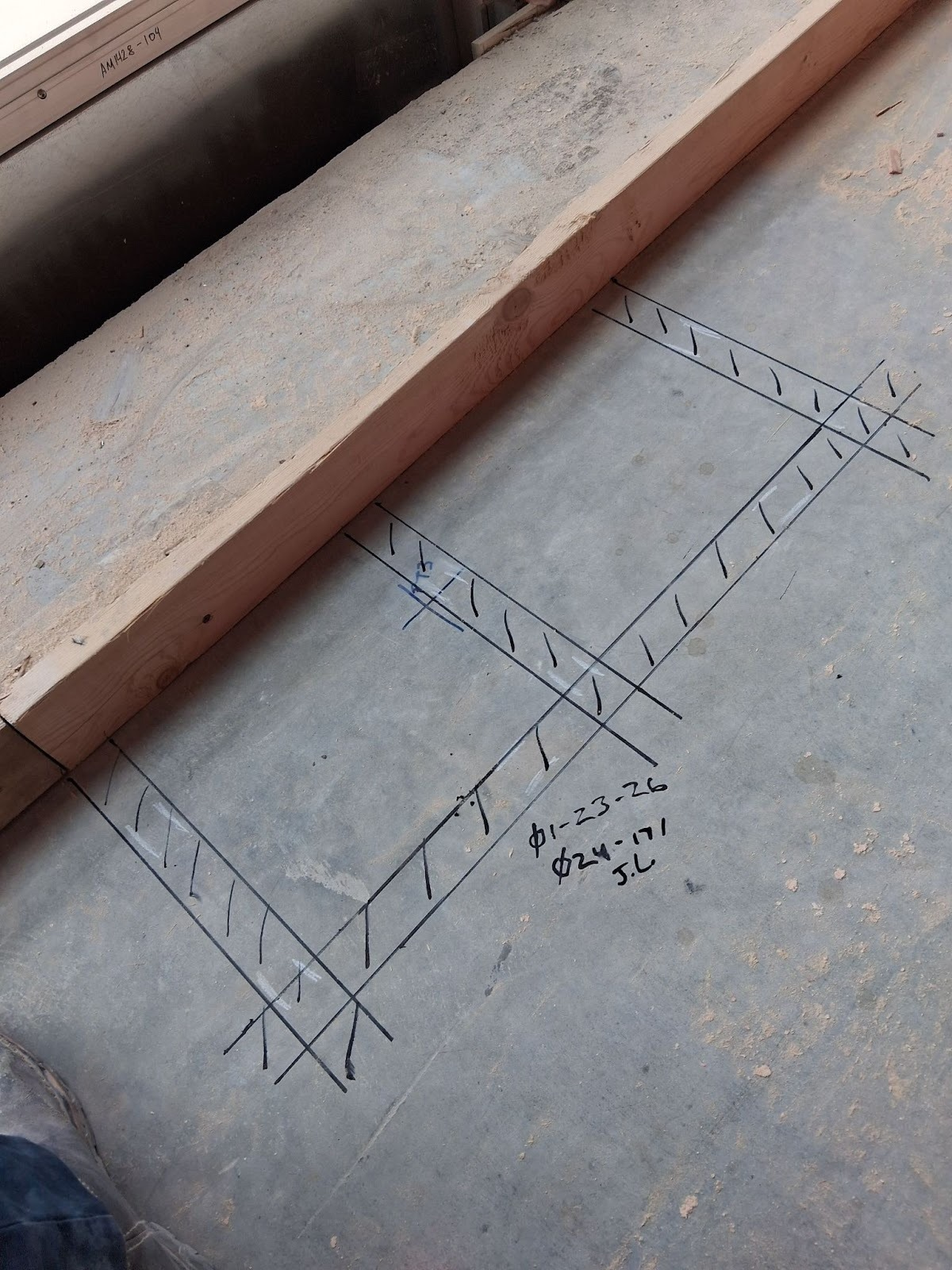

3. Insist on Ground Penetrating Radar (GPR) Scanning

Before a single cut or core, subsurface scanning should always take place. Ground Penetrating Radar (GPR) identifies rebar, post-tension cables, and conduit embedded within the concrete.

Cutting blindly is one of the fastest ways to cause damage or injury. A company that includes GPR as part of its workflow demonstrates technical competence and attention to detail.

At Kansas City Coring & Cutting, every cutting and coring project begins with scanning. It eliminates guesswork, reduces downtime, and ensures every move we make aligns with engineering and safety requirements.

Actionable Tip:

Ask whether scanning is performed in-house or outsourced. In-house scanning saves time, improves accuracy, and keeps control under one roof.

4. Evaluate Communication and Coordination Skills

Technical ability is only part of what makes a great partner. Coordination and communication often determine whether a job runs smoothly.

A professional contractor will provide detailed scopes, timelines, and coordination plans before work begins. They will also communicate proactively with site supervisors, other trades, and facility management teams to minimize conflicts.

When working in occupied spaces or complex sites, communication is everything. Cutting and coring teams must plan around operations, schedule noise-sensitive work, and maintain constant alignment with other trades.

Actionable Tip:

During your initial consultation, pay attention to how quickly and clearly the company responds. A partner who communicates well before the contract is signed will likely continue to do so during the job.

5. Look Beyond the Price Tag

Lowest bid rarely equals lowest cost. A poorly executed cut can create rework, repair expenses, or liability issues that erase any initial savings.

A qualified partner will deliver more than accurate pricing — they will provide value through precision, reliability, and reduced downtime. When you hire based on skill and professionalism, you protect your project’s schedule, safety, and reputation.

Actionable Tip:

Request a full scope of work with clear inclusions and exclusions. Compare not only prices but processes. Ask how the contractor handles cleanup, containment, and waste management.

6. Prioritize Professionalism and Accountability

How a company shows up on site says as much about their culture as their equipment does. Uniformed crews, clean vehicles, and organized staging areas reflect professionalism and discipline. A partner who respects the jobsite environment is far more likely to respect the structure itself.

Accountability also extends to documentation. Daily safety logs, job photos, and completion reports show transparency and attention to detail. If a contractor cannot produce those records easily, it may be a sign of disorganization.

Actionable Tip:

Ask for proof of insurance, training certifications, and safety protocols before work begins. A quality partner will have all of these ready to share.

The Bottom Line

Hiring a qualified concrete cutting partner is not about finding the cheapest crew — it is about choosing the most reliable one. The right team protects your schedule, your structure, and your reputation.

At Kansas City Coring & Cutting, our commitment to precision, safety, and communication has earned us the trust of contractors across the region. We use the latest equipment, maintain a culture of accountability, and deliver results that stand up to inspection every time.

If you are planning a project that involves cutting, coring, or selective demolition, have a conversation with us. We will help you evaluate your scope, identify potential risks, and build a plan that ensures your project runs smoothly from start to finish.

Recent Posts