How Ground Penetrating Radar (GPR) Is Transforming Construction Safety and Structural Integrity

Every concrete structure hides a story beneath its surface. Inside a slab or wall, there may be rebar, post-tension cables, conduits, and voids — all of which are invisible to the naked eye. Striking one of these components during cutting or drilling can lead to costly damage, electrical hazards, or even structural failure. This is where Ground Penetrating Radar (GPR) technology comes in.

At Kansas City Coring & Cutting, GPR scanning has become a standard part of our process. It allows us to “see” inside concrete before cutting begins, giving our technicians and clients total confidence in safety, accuracy, and project success.

The Science Behind GPR

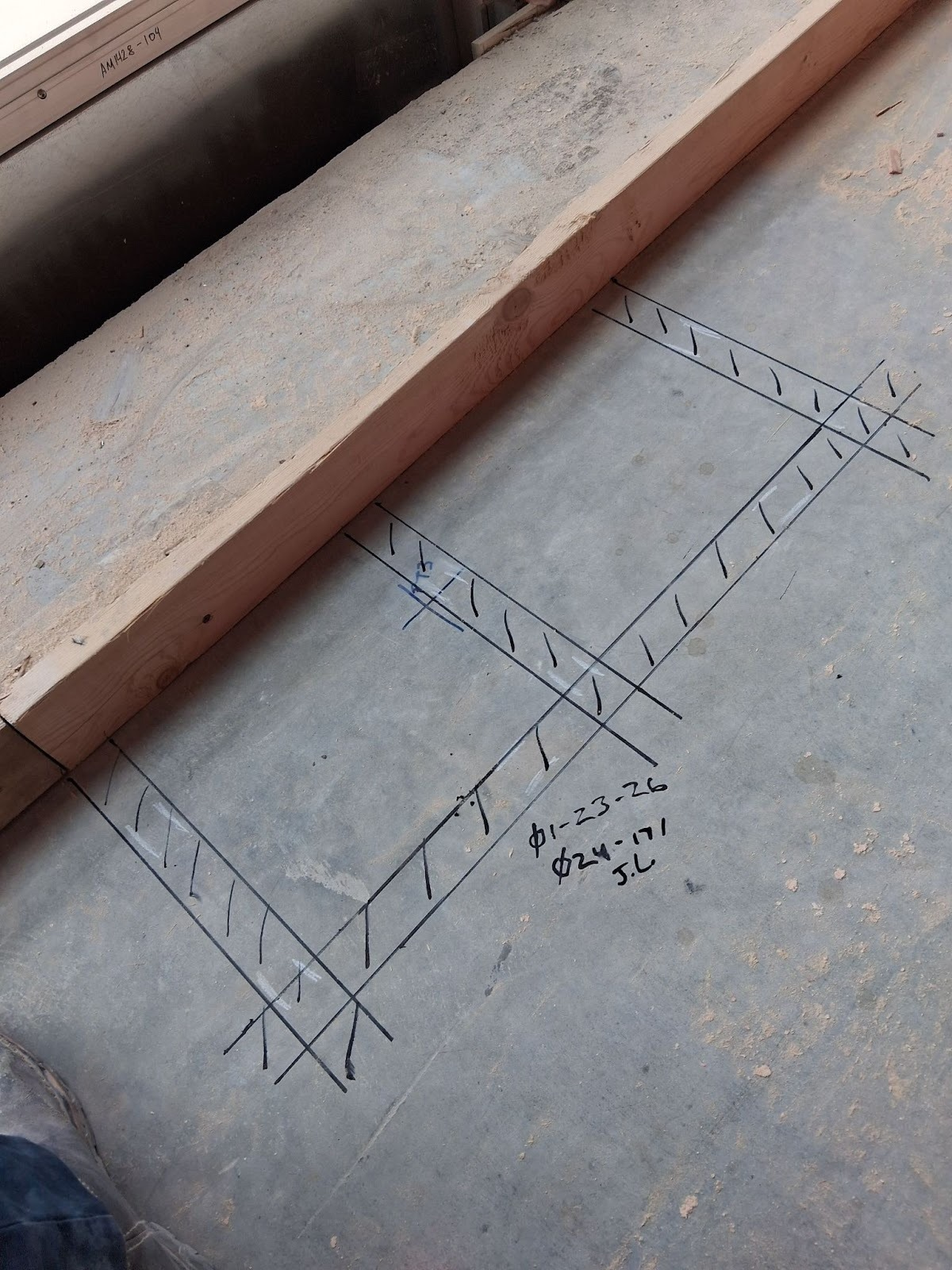

GPR works by sending high-frequency radio waves into the concrete. When those waves hit a material with a different density — such as steel, conduit, or air pockets — they bounce back to a receiver. The time it takes for those reflections to return is measured and processed into an image or map of what lies below the surface.

The result is a clear view of what cannot be seen by eye or even by X-ray. Modern GPR systems can detect objects as small as a quarter inch in diameter and as deep as several feet, depending on the concrete thickness and composition. The technology is non-destructive, fast, and safe for use in any environment, making it ideal for both new construction and renovation projects.

Why GPR Scanning Is Critical for Safety

Cutting or coring without scanning is like performing surgery without imaging. It introduces unnecessary risk and uncertainty. GPR scanning eliminates that risk by identifying hidden dangers before work begins.

For example, cutting through a post-tension cable can release thousands of pounds of stored energy instantly, which can cause serious injury and structural damage. Severing live electrical conduit can lead to electrocution or system outages. Even nicking rebar can weaken the structural integrity of a wall or slab.

By using GPR, these risks are removed. The scanning process provides the information needed to plan safe cutting paths and core drilling locations. It also ensures compliance with building codes, safety standards, and project engineering requirements.

What GPR Commonly Reveals

In our daily work, GPR reveals a variety of critical elements that are often overlooked during design or renovation planning. These include:

Steel rebar and mesh reinforcement grids

Post-tension cables under tension

Electrical and communication conduit

Embedded plumbing and piping

Voids, honeycombing, and cracking within concrete

Structural inconsistencies or repairs from past modifications

Identifying these details in advance prevents unexpected downtime, equipment damage, and costly rework.

Real-World Applications of GPR Scanning

GPR is valuable in almost every type of construction or renovation project. It is especially vital for hospitals, schools, government buildings, and data centers where safety and uptime are critical.

In commercial renovation projects, GPR helps determine where openings can be safely made for utilities, doors, or windows. On infrastructure projects, it is used to locate reinforcement before coring bridge decks or structural columns. For historic restoration, it allows teams to evaluate structural integrity without destructive testing.

In each case, the outcome is the same: fewer surprises, safer work, and a more efficient project schedule.

GPR vs. Traditional Scanning Methods

Before GPR, many contractors relied on outdated or invasive methods to locate subsurface materials. X-ray scanning, for example, requires access to both sides of the structure and poses health and logistical challenges. Physical probing or exploratory drilling can damage the structure before cutting even begins.

GPR offers a safer, faster, and more precise alternative. It can be performed from a single side, produces instant results, and does not disrupt surrounding operations. For clients, that means less downtime, fewer permits, and more accurate project planning.

Kansas City Coring & Cutting’s GPR Advantage

At Kansas City Coring & Cutting, GPR scanning is not an optional service — it is a standard step in our process. Before any cutting, coring, or drilling begins, our technicians perform a detailed GPR scan to map out every embedded object. This data is reviewed alongside project drawings to ensure our work aligns perfectly with structural and safety requirements.

Our team uses state-of-the-art scanning equipment operated by trained professionals who understand both the technology and the construction environment. That combination of expertise and technology allows us to make informed decisions on every job, no matter the complexity.

Building Safer, Smarter Structures

As construction technology continues to evolve, GPR scanning stands out as one of the most important advances for safety and quality assurance. It provides the insight needed to work confidently, protect workers, and preserve the integrity of every structure.

For contractors, engineers, and facility managers, working with a partner who uses GPR is not just a precaution — it is a guarantee of professionalism.

At Kansas City Coring & Cutting, we bring precision, safety, and innovation to every project. GPR is more than a tool for us. It is the foundation of how we build smarter, safer, and more reliable results across Kansas City and beyond.

Recent Posts